Smart manufacturing has changed how we run factory operations. IoT implementation can cut costs by up to 40%. Manufacturers in today’s competitive world constantly look for ways to optimize production and reduce expenses. We’ve found that connected systems create new opportunities to save money and boost efficiency.

IoT smart manufacturing turns traditional factories into intelligent facilities that monitor themselves. These technologies collect and analyze data immediately to help us spot inefficiencies fast. The shift to smart manufacturing industry 4.0 principles isn’t just an upgrade anymore – it’s essential for companies that want to stay competitive.

IoT’s biggest effect comes from its power to predict and prevent expensive downtime. We can now spot potential issues before equipment fails. This approach helps machines last longer and stops unexpected production delays that used to waste resources and drive up operating costs.

IoT Reduces Factory Downtime by Enabling Predictive Maintenance

Automotive factories lose over $600 million each year due to unplanned downtime. These losses go beyond just money. Production stops lead to missed deadlines, quality problems, and lost customer trust. Smart manufacturing with IoT helps solve this big problem by watching equipment and fixing issues early.

The key change happens when companies stop fixing things after they break and start preventing problems. Old factories usually rush to repair broken equipment. Smart manufacturing works differently. Connected sensors watch how machines work all the time. They notice small changes in vibration, temperature, or patterns that might mean trouble is coming.

These sensors work like the factory’s nervous system. They collect huge amounts of data that nobody watched before. Cloud platforms analyze this data and spot patterns that humans can’t see. Companies that started using digital tools early have seen great results. They cut unplanned downtime by 17% and made production 8% better.

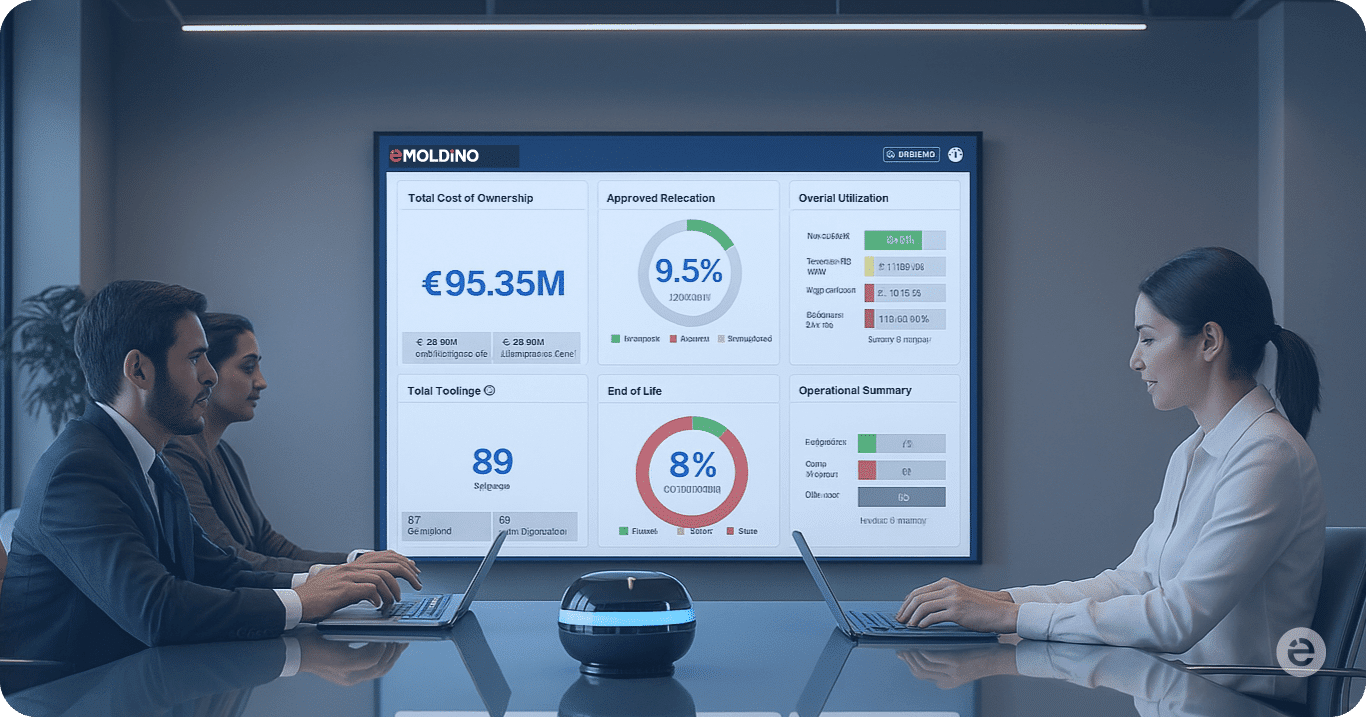

To cite an instance, Continental, a leading automotive company, started using AI to manage their tools better. They wanted to see their manufacturing operations more clearly. The company tested the system in stages before using it everywhere. The results were impressive:

17% reduction in unplanned downtime

8% improvement in overall production performance

100% adherence to preventive maintenance schedules

Continental saw such good results that they rolled out this solution to all their factories worldwide. This created the same high standards everywhere.

Research shows that digital tool management helps save money and makes tools last longer. Companies can cut costs by 12% each year. They have fewer delays and make fewer bad parts because they can predict what tools they need. Better visibility also helps tools last longer.

Many companies still use old methods. About 48% rely on manual work or spreadsheets to track manufacturing data. These outdated ways slow everything down. Workers can’t use immediate tool data to make good decisions. When machines break, operators often have no data to help fix problems. This leads to longer repair times and more downtime.

Smart manufacturing creates digital copies of real equipment. These virtual twins can show what might happen under different conditions. Maintenance teams can test their fixes on these copies first. This reduces the risk of making things worse during repairs.

IoT devices and cloud computing are the life-blood of modern tool management. Sensors inside manufacturing systems track how everything works in real time. This gives unprecedented insight into equipment condition. Central platforms store all this data. Teams can access it anywhere and respond quickly to new needs.

Tool digitalization does more than just maintenance. It finds production bottlenecks, makes tools last longer, and helps move production around based on available tools. Manufacturers get clear information about supplier capacity. This helps them adjust quickly when demand changes.

Automated maintenance alerts show how well these digital platforms work. They help tools last longer and work better. Suppliers can meet their contract requirements more easily. Manufacturers can watch maintenance work happen. This ensures quality stays high and operations stay flexible.

Talk to eMoldino expert to learn how these advanced IoT systems can work in your factory. Their methods have helped automotive makers save millions. Case studies show proper setup has saved about £52,000,000 through better costs, faster cycles, and less risk.

Manufacturers must use advanced digital tool systems to avoid huge losses from unexpected downtime. These solutions help companies use data and stay connected. This changes how maintenance works, makes operations more reliable, and keeps companies competitive in tough manufacturing markets.

About the author

eMoldino

eMoldino

eMoldino aims to digitalize, streamline, and transform your manufacturing and supply chain operations. We help global manufacturers who want to drive corporate innovation while maintaining the core values of collaboration and sustainability. Talk with us to learn more →

Did you enjoy reading this article?

0 / 5. Vote count: 0

Explore Our Latest Posts