The Imperative for a Data-Driven Strategy

In 2024, it is imperative for businesses to adopt a more integrated, data-driven approach. Utilizing advanced analytics and IoT technologies can shed light on product flows and interactions within the supply chain, thereby identifying both inefficiencies and opportunities.

Currently, a significant challenge remains as 43% of organizations report limited to no visibility into their tier one suppliers’ performance, according to KPMG.

Addressing the Visibility Gap

In outsource manufacturing, a critical challenge emerges between the release of orders and the start of outsourced part production: the visibility gap. This gap often causes Original Equipment Manufacturers (OEMs) to lose sight of the process, leading to inefficiencies and adaptability issues. Bridging this gap is essential for manufacturers to enhance supply chain fluidity and to respond proactively to the dynamic demands of the market.

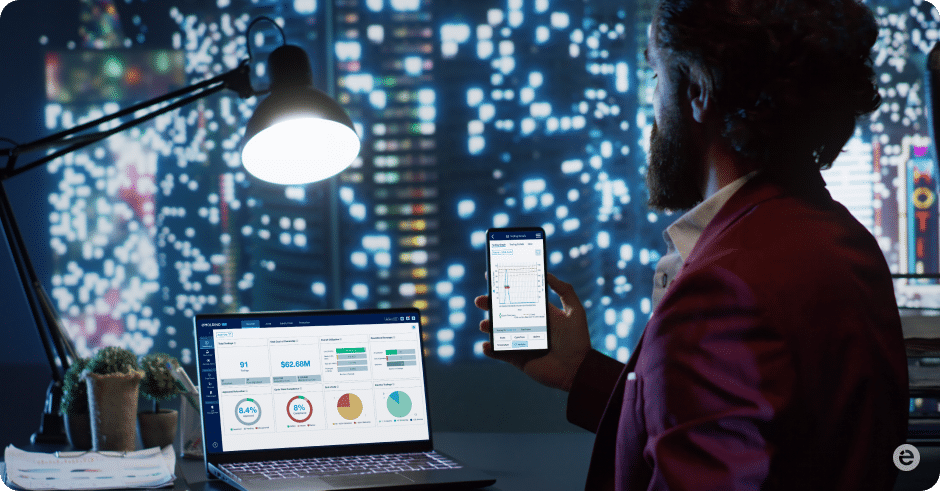

Case Study: Transforming Supply Chain Management

The automotive giant identified critical visibility gaps in its supply chain affecting production, product and parts capacity, and asset management. These issues significantly impacted the company’s operations, contributing to approximately $22,184,140 million in lost car sales weekly due to supply chain inefficiencies.

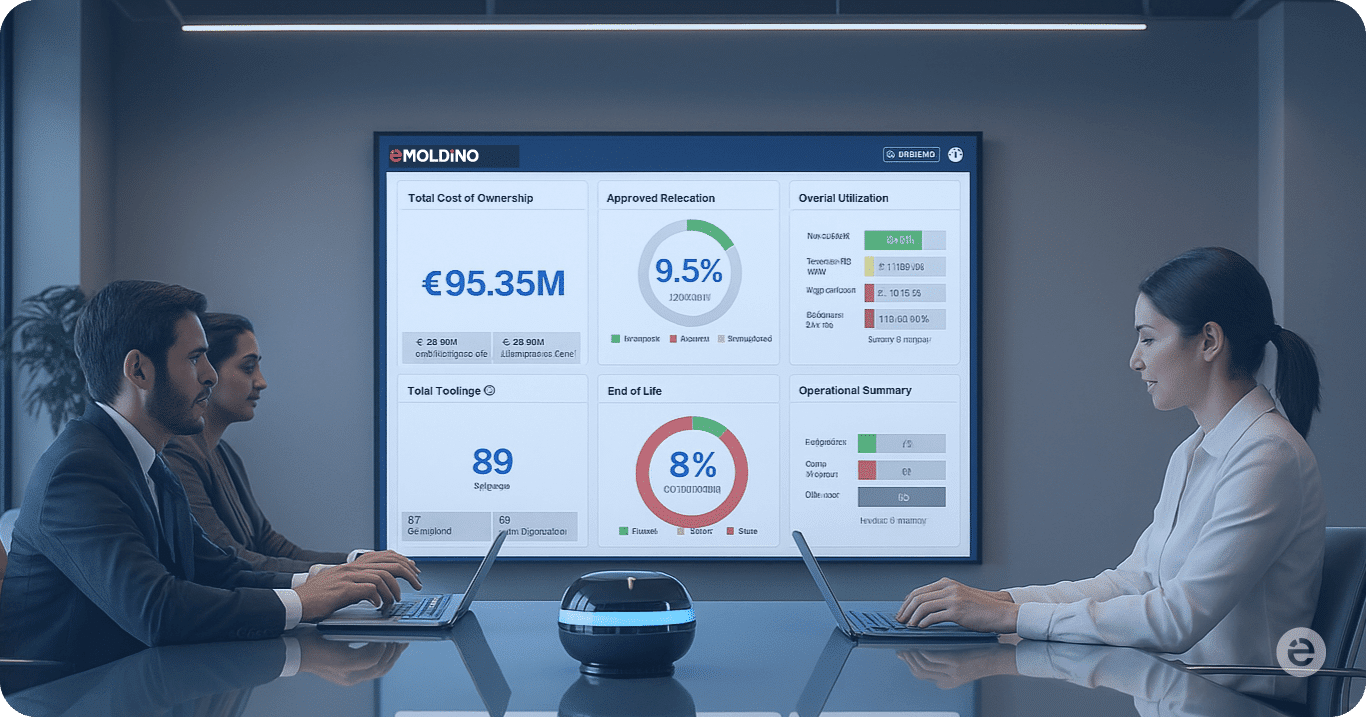

To address these challenges, the automotive company implemented an advanced analytics solution. This involved deploying 5000 sensors across 5000 primary tools, providing:

- Real-time Production Data: Enabling the company to monitor production processes in real time.

- Capacity Management and Delivery Risk Mitigation: Allowing the company to proactively manage production capacity and mitigate risks associated with delivery timelines.

- End of Life Prediction: Helping the company predict the lifecycle of tools to plan replacements or maintenance more effectively.

- Supplier Benchmarking: Offering the company the ability to compare and evaluate supplier performance systematically.

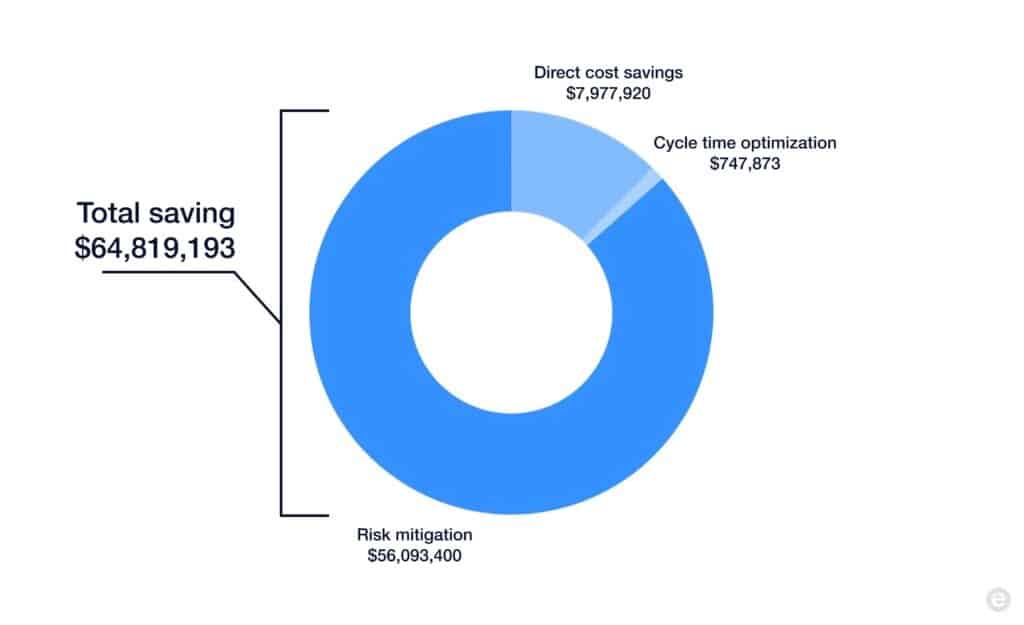

This pilot project quickly demonstrated substantial benefits, resulting in potential cost savings and efficiency improvements valued at approximately $64,819,193. The breakdown includes $7,977,920 from direct cost savings, $747,873 through cycle time optimization, and $56,093,400 from risk mitigation, showcasing the significant impact of the analytics solution across various operational facets.

Conclusion

The case of this automotive leader and eMoldino underscores the critical role of digital innovations in revolutionizing supply chain management. By embracing a data-driven approach, companies can not only foresee and effectively manage risks but also improve overall operational agility and sustainability, securing a robust competitive advantage in the marketplace.

About the author

eMoldino

eMoldino

eMoldino aims to digitalize, streamline, and transform your manufacturing and supply chain operations. We help global manufacturers who want to drive corporate innovation while maintaining the core values of collaboration and sustainability. Talk with us to learn more →

Did you enjoy reading this article?

5 / 5. Vote count: 1

Explore Our Latest Posts