“Executives face modern supply chain challenges, including real-time production process tracking, inefficient supplier communication, and financial risks. This article offers strategies for data utilization, technological transformation, and strengthening supplier partnerships, aiming for a resilient and innovative supply chain.”

Michael, a seasoned Chief Supply Chain Officer in the automotive sector, diligently handles his responsibilities but is concerned about his grip on the parts production process. He identifies significant issues: the need for real-time production tracking and poor supplier engagement methods, making every project a gamble. Delays or subpar parts could lead to financial losses of up to $1,000,000 per hour. Amidst rapid industry changes, Michael is continuously battling to enhance his supply chain’s efficiency and reliability.

The challenge is balancing caution with action—too much of either harm the business. The key is to make early, informed, data-driven decisions to address potential issues preemptively.

CSCOs Strategic Response

Many leaders need proactive measures to bolster supply chain resilience when facing challenges like operational bottlenecks from delays or poor-quality parts. Forward-thinking executives view these hurdles as chances to gain a competitive advantage by investing in for operational efficiency, technological innovation, and sustainability.

1. Harnessing Data for Innovation

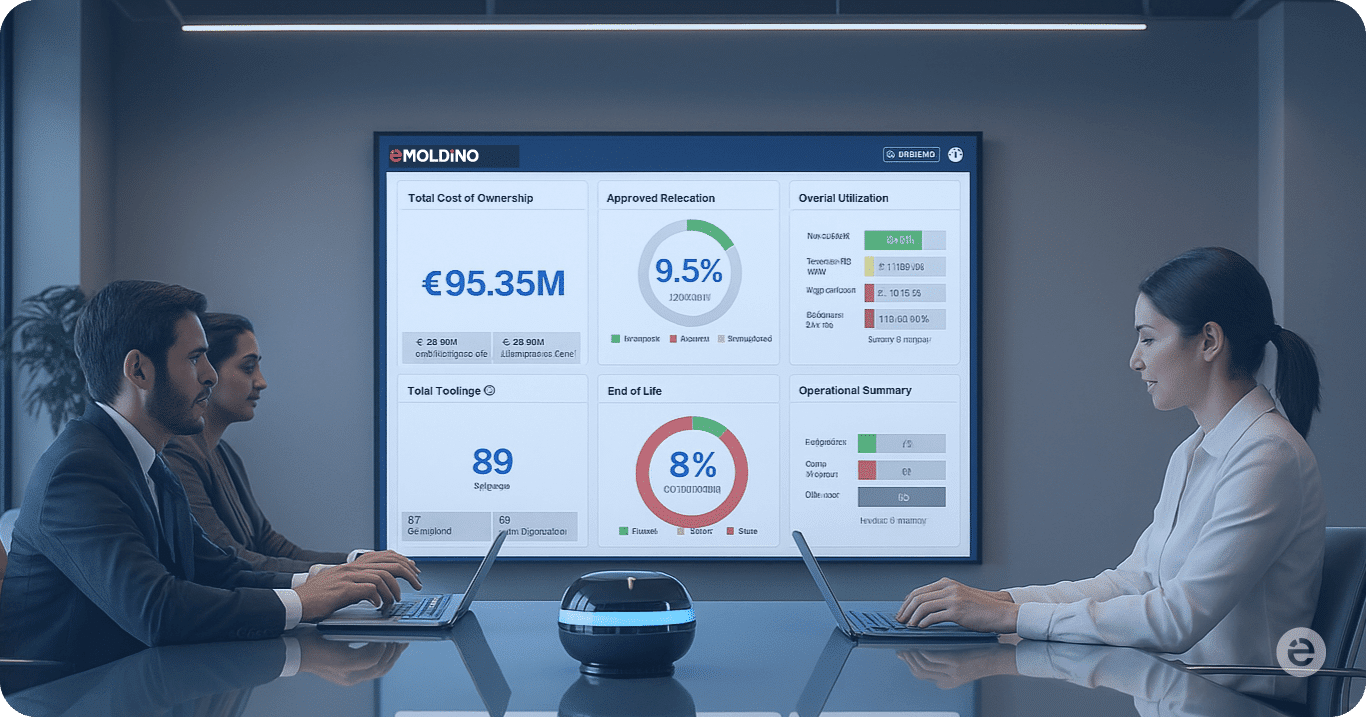

With 60-70% of tooling data often going unnoticed, there’s a significant opportunity for innovation and efficiency in discrete manufacturing data. CSCOs can unlock this potential by deeply analyzing this data, transforming every unused bit into a strategic asset for improved manufacturing responsiveness. This approach is revolutionary, enhancing operational efficiency and cost-effectiveness.

2. Transforming Operations with Technology

Transitioning from manual to real-time, automated data processing and utilizing AI for optimization presents a substantial opportunity to reduce financial burdens. The seemingly small 1% error rate in manual processes, when viewed in the context of OEMs’ vast operations, significantly drains resources. Adopting tooling digitalization does more than rectify errors; it transforms the operational ecosystem, providing the clarity and accuracy needed to eliminate unnecessary expenses while maintaining quality.

3. Supplier Relationship Management

In the face of rapidly changing markets, executives prioritize optimizing component sourcing strategies, aiming to align production tightly with actual demand to bypass historical inefficiencies and costly measures like emergency airlifting. This strategic shift avoids substantial expenses and fosters a more resilient and agile supply chain. Central to this adjustment is embracing real-time data sharing with suppliers, enhancing collaboration, and opening avenues for cost reduction and process improvement. Such partnerships align production with demand, offering agility in response to market shifts, and embed a fundamental transformation towards a dynamic, cost-efficient supply chain poised for future triumphs.

4. Sustainability & ESG

Despite economic challenges, companies are intensifying their focus on environmental responsibilities, particularly with Scope 3 emissions, which constitute over 70% of a business’s carbon footprint on average. Leaders acknowledge that sustainability and ESG efforts cut costs by improving efficiency and alleviating the environmental and financial strains from operational inefficiencies, like the automotive industry’s issues with high scrap rates and expensive late deliveries.

Adopting tooling digitalization plays a key role in overcoming these challenges by enhancing tooling efficiency and optimizing maintenance and production. This significantly reduces waste, energy consumption, and unnecessary logistics, marking a shift toward more sustainable and efficient operations.

Final Thoughts

How will executives tackle the critical challenge of balancing efficiency with environmental responsibility in their supply chains?

The key is to strategically focus on digitalization and supplier collaboration—an approach that positions companies to capitalize on change, propelling innovation and sustainable development in alignment with efficiency and environmental responsibility.

About the author

eMoldino

eMoldino

eMoldino aims to digitalize, streamline, and transform your manufacturing and supply chain operations. We help global manufacturers who want to drive corporate innovation while maintaining the core values of collaboration and sustainability. Talk with us to learn more →

Did you enjoy reading this article?

5 / 5. Vote count: 2

Explore Our Latest Posts