Scrap reduction in manufacturing cuts costs and creates waves of benefits across the production process. Manufacturing giants have cut their expenses by up to 40% by using targeted scrap reduction strategies. Poor scrap control directly eats into profit margins. Even small improvements can save costs by a lot and boost operational sustainability.

Manufacturing cannot avoid scrap, but companies can minimize its effects with the right approach. High scrap rates disrupt production efficiency and reduce output quality that ended up hurting customer satisfaction. A low scrap rate shows an operation runs efficiently with minimal waste and better output. Companies can optimize resource usage through strategic part layouts that produce less scrap material. Reducing scrap material helps the environment by saving natural resources, cutting pollution, and lowering waste—while improving the company’s bottom line.

Manufacturers Cut Scrap to Slash Costs by 40%

Manufacturing companies have found that there was a direct link between scrap management and profits. A major industrial packaging manufacturer lost millions yearly in wasted tin, steel, and coating. They fixed this with targeted improvements that cut scrap by 22% in just five weeks, saving $1.2 million each year. Many companies now turn their industrial waste into valuable resources through well-laid-out scrap metal recycling programs that cut raw material costs.

How scrap in manufacturing affects profitability

Material costs make up one of the biggest chunks of manufacturing expenses. High scrap rates trigger a chain of financial losses across production. Companies pay twice when they generate too much scrap – once to buy materials and again to dispose of waste.

Scrap affects profitability through several channels:

Increased raw material costs: Companies must buy extra materials to replace production waste

Higher waste management expenses: Moving, disposing, and treating scrap adds major operational costs

Reduced productivity: Managing scrap and fixing products cuts overall efficiency

Lower competitive position: Higher production costs can force price hikes or profit cuts

The scrap rate—calculated by dividing unusable units by total units produced—shows how efficient manufacturing really is. High scrap rates point to quality control problems and operational issues that eat into profits. Companies that track and work to lower their scrap rates usually make better profits than rivals who ignore this metric.

Why reducing scrap is a strategic priority

Today’s competitive manufacturing world requires companies to optimize and cut costs. Scrap reduction is crucial as materials constitute a significant portion of manufacturing costs. Lower scrap rates mean less need for raw materials, saving money, especially with expensive materials like metals and specialized components. Effective scrap reduction gives companies an edge, allowing them to boost profits or lower prices to gain market share. For instance, one manufacturer cut costs by 22% in five weeks—35% better than their goal. Rising waste disposal costs and stricter regulations make less scrap essential for lower costs and better sustainability. Companies generating less waste operate more efficiently, with reduced downtime and faster production. While scrap is often seen as unavoidable, excessive waste negatively impacts profits. Identifying the sources of scrap through root cause analysis reveals that poor processes, maintenance issues, incorrect setups, tool problems, and inadequate training are common culprits. Companies prioritizing scrap reduction in their improvement plans position themselves to thrive in a landscape where efficiency is vital for survival.

Common causes of manufacturing scrap

Production processes generate scrap from many sources. Equipment malfunctions hurt quality and create defective parts that end up as waste. Old procedures don’t keep up with new technology, which leads to more waste. Quality standards and tolerances also make a big difference—strict specs often mean more rejected parts.

Each operator tends to develop their own methods because standard work isn’t consistent. This makes it hard to find what’s causing problems. Unstable equipment adds unpredictable variables that show up as customer complaints or internal scrap. Machines drift away from specs when maintenance falls behind, so operators have to keep adjusting settings to get the quality right.

How poor processes and training contribute to waste

Bad processes are the foundations of scrap generation in manufacturing. Old and inefficient production methods naturally create more waste. Quality suffers from wrong setup procedures, poor maintenance, and weak process controls.

Poor training makes these problems much worse. Operators make mistakes that create scrap when they don’t get proper instruction. Industry sources tell us that untrained workers often produce defective products. The problems get bigger when weak escalation systems let small issues turn into batch defects—teams log the problems but don’t fix them properly.

Process changes need careful management too. Production creates “silent killers” when machine settings, materials, or tooling change without proper documentation. Quality teams can’t trace problems to their source when changes happen without their input.

The role of raw material quality in scrap generation

Raw material quality determines scrap rates in manufacturing. Materials that don’t meet specs get rejected before production even starts. This hits companies hard since materials usually cost the most in manufacturing.

Materials that aren’t consistent lead to unpredictable results. Prompt scrap has better quality than obsolete scrap, which contains more impurities. Steel manufacturers face tough challenges as scrap quality goes down while product standards keep getting higher.

The effects go beyond just rejection rates. Bad materials need more energy per ton of output. Some contaminants stick around as “tramp” elements that permanently affect product quality because they can’t be removed during processing.

Manufacturing environments need budget-friendly solutions to tackle these issues. The answer lies in reliable quality control, good training programs, standard processes, and smart material sourcing.

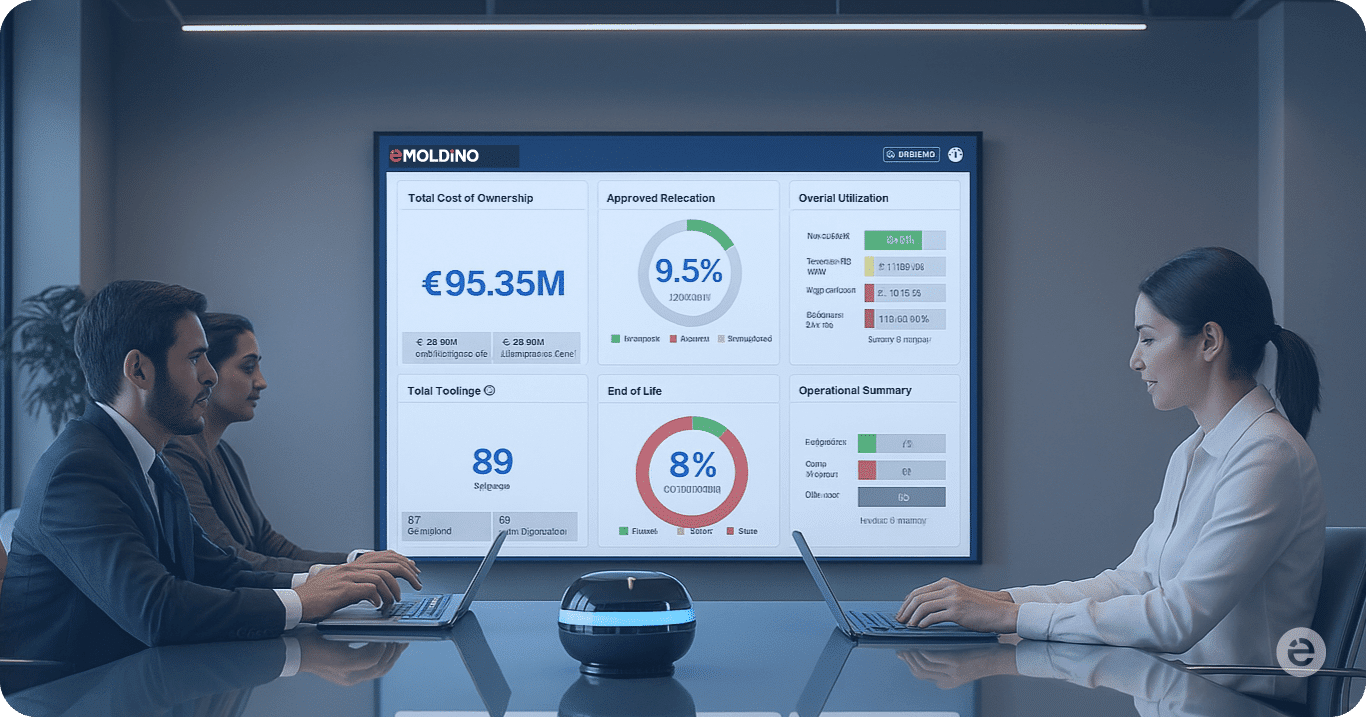

How Metrics Like Scrap Rate and OEE Reveal Hidden Waste

Good measurement is the life-blood of any successful scrap reduction program. Companies that use strong metrics can see waste that was hidden before. This helps them make specific improvements and save substantial costs.

What is the average scrap rate in manufacturing?

Scrap rate is a basic metric that shows what percentage of manufactured parts fail quality standards. Most manufacturing operations see normal scrap rates between 2% and 5%. Companies with rates below this range show excellent efficiency. Those above 5% likely face major quality control challenges that need quick attention.

You can easily calculate the scrap rate. Just divide unusable units by total units produced and multiply by 100 for the percentage. This simple calculation tells you a lot about manufacturing efficiency. High scrap rates point to production issues that could come from bad materials, machine problems, or old procedures.

Using OEE to identify inefficiencies

Overall Equipment Effectiveness (OEE) remains the best way to measure manufacturing productivity. It shows what percentage of planned production time actually produces good parts. This detailed metric looks at three key areas:

Availability – accounts for downtime losses

Performance – measures speed losses

Quality – considers defects and rework

The quality part of OEE links directly to scrap reduction work. It counts parts that don’t meet quality standards, including ones that need rework. Small quality improvements can change OEE scores substantially. A quality rate increase from 83% to 93% can push OEE from 59.9% to 67.2%.

Many manufacturers’ actual OEE turns out lower than predicted—often 25-30%, while managers think it’s 20-30 points higher. This gap shows the “hidden factory” problem, where undocumented waste eats up 20-40% of manufacturing capacity.

Why quality metrics help cut scrap

Quality metrics light up areas where production creates invisible waste. These measurements help companies spot specific problems, calculate their effect, and make targeted fixes.

Companies that track scrap rates carefully can find exactly where their manufacturing needs improvement. The financial benefits are clear—average manufacturers spend up to 2.2% of yearly revenue on scrap and rework. Even small improvements add up fast. A $100 million company that cuts scrap by just 10% saves $220,000 every year.

Ground applications prove these metrics work well. One factory had surface defect problems but solved them by adding measurement systems. They found what caused their 5% scrap rate and ended up bringing it close to zero. Aerospace companies that use process audits have cut internal defects by 73% through careful measurement and monitoring.

Companies that make use of these quality metrics can see waste that was hidden before. This creates chances to cut costs across their operations.

How Lean Manufacturing and Root Cause Analysis Reduce Scrap

Lean manufacturing gives proven frameworks to tackle scrap head-on through systematic waste elimination. Lean methodologies target the mechanisms rather than just symptoms of scrap generation, unlike traditional approaches.

What is the process of laying out parts to minimize scrap?

Strategic part nesting is a fundamental technique to minimize manufacturing scrap. The process needs careful arrangement of multiple parts within a single material sheet that maximizes utilization. Companies can save materials by nesting different part types in a common die. This eliminates separate tooling requirements. Designers must think over production volumes first. The larger part should have greater production needs to prevent material waste when only smaller parts are needed. Engineers must also watch for material grain direction, especially when forming high-carbon or high-strength steel. Bending parallel to grain could cause cracking.

Implementing lean principles to reduce scrap material

Lean manufacturing’s core philosophy aims to eliminate waste in all forms. This approach removes anything that doesn’t add customer value. Companies use techniques like 5S (Sort, Set in Order, Shine, Standardize, Sustain) to organize workspaces and cut inefficiencies. Shadowboards are great visual management tools that help locate equipment quickly and minimize wasted motion. Regular equipment maintenance stops inaccurate cuts and poor tolerances that create scrap. Good operator training helps personnel produce accurate results with fewer errors.

Conducting root cause analysis for long-term gains

Root cause analysis (RCA) gives a well-laid-out framework to identify the basic reasons behind scrap generation. The DMAIC process (Define, Measure, Analyze, Improve, Control) shows a systematic way to solve problems. Teams identify specific issues that need resolution in the Define phase. The Measure stage sets quantifiable baseline measurements to compare. Investigators find the main causes behind problems during the Analyze phase. The Improve stage puts solutions in place to address identified causes. The Control phase keeps these improvements going over time.

The 5 Whys technique is another powerful RCA tool. A manufacturing company showed this by eliminating “last piece material scratch” scrap through systematic questioning without extra investment.

How Technology Helps Cut Scrap in Real Time

Modern technology gives manufacturers effective tools to curb scrap with immediate analysis that delivers quick financial gains. Companies that adopt these technologies have cut their scrap rates by over 20%. This improvement comes from constant monitoring and quick response systems.

MES systems and real-time monitoring tools

Manufacturing Execution Systems (MES) show shop floor operations as they happen. This helps manufacturers spot quality issues right away. These systems keep track of key production metrics like scrap counts that measure defective or unusable units. MES platforms detect problems automatically and limit bad parts and wasted materials.

Real-time monitoring catches process problems that might go unnoticed otherwise. Brief production stops seem minor but cause more production losses than longer breakdowns. These short interruptions stay hidden from management without automated data capture and add up to create more scrap. A real example showed daily temperature changes affecting just 0.3% of production cycles created 4,181 bad parts yearly per tool. Each defective part cost about $5.

Predictive maintenance to prevent equipment-related scrap

Predictive maintenance uses sensor data and AI algorithms to spot equipment failures before they happen. This approach cuts scrap by stopping defects from failing machines. Research shows this method can reduce waste by 10-20% and boost worker productivity by 5-20%.

Fortune Global 500 companies lose about $1.5 trillion each year due to unexpected downtime. Advanced analytics and machine learning algorithms help manufacturers catch subtle equipment changes that people might miss. This allows teams to fix issues before quality drops.

Using data analytics to optimize production

Data analytics reshapes manufacturing by uncovering hidden patterns in production processes. Machine learning models have achieved 4.4% lower scrap rates by optimizing parameters. These systems analyze operating conditions and flag efficiency drops immediately.

Digital twins run simulations before physical production starts to find potential waste sources. You can talk to an eMoldino Project Expert about setting up advanced analytics. These tools predict when specific limits will be exceeded and trigger quick fixes before defects create too much scrap.

Advanced analytics give manufacturers the power to make informed process changes that boost productivity, cut costs, and minimize waste.

The Bottom Line: Strategic Scrap Reduction Drives Manufacturing Success

Manufacturing giants achieve remarkable cost reductions through strategic scrap management. Companies that implement targeted scrap reduction initiatives cut expenses by up to 40%. These initiatives also boost operational sustainability. Material waste cuts directly into profit margins. This makes scrap reduction a strategic priority, not just an operational concern.

Several factors cause scrap generation. Equipment malfunctions, outdated procedures, poor training, and substandard raw materials all add to the problem. Companies need to tackle these basic drivers through detailed approaches. They must set up resilient measurement systems to track metrics like scrap rate and OEE. These indicators reveal hidden inefficiencies that drain resources quietly. Top manufacturers keep scrap rates below 5%. This gives them substantial competitive advantages.

Lean manufacturing principles give proven frameworks to tackle waste systematically. Strategic part nesting, 5S implementation, and visual management tools help cut material loss. Teams can spot and eliminate problems permanently with root cause analysis techniques like DMAIC and the 5 Whys method.

Technology plays a vital role too. MES systems show production processes through up-to-the-minute data analysis. Predictive maintenance stops equipment-related defects before they happen. Data analytics uncovers hidden patterns that let teams take action early to prevent scrap.

The evidence stands clear. Manufacturers who make scrap reduction a priority see benefits beyond cost savings. They save natural resources and cut pollution. Their waste disposal costs drop. This strengthens their market position. Companies should see scrap not as an inevitable byproduct but as a chance for continuous improvement. Every percentage point drop in scrap rate brings substantial financial gains. These environmental benefits spread throughout the organization.

About the author

eMoldino

eMoldino

eMoldino aims to digitalize, streamline, and transform your manufacturing and supply chain operations. We help global manufacturers who want to drive corporate innovation while maintaining the core values of collaboration and sustainability. Talk with us to learn more →

Did you enjoy reading this article?

0 / 5. Vote count: 0

Explore Our Latest Posts