AUTOMOTIVE

Overcoming Digital Tech Adoption Challenges in Automotive Manufacturing

2023.12.19 | Updated: 2023-12.29

In an era where technology and innovation drive industries forward, the automotive industry, long known as a leader in pioneering advancements, now grapples with an ironic dilemma: the challenge of digital adoption. From tooling fleets scattered globally to the complexities of intricate supply chains, a seamless digital solution becomes desirable and essential. This calls for exploring the industry’s current predicament and looking into potential remedies.

Hurdles to Overcome

The automotive industry’s ambition to harness digitalization, especially in tooling, is rife with challenges. One of the towering concerns is financial. In an age where technological advancements can change overnight, many Fortune 500 companies are cautious despite owning vast tooling fleets. They’re caught in a dilemma: Will the potentially significant investments in digitalizing tooling provide a sustainable edge or become obsolete too soon?

Further complicating this is the industry’s intricate supply chain. Imagine coordinating a unified digital platform across suppliers dispersed globally, each with its operational nuances. This isn’t just about deploying technology; it’s about synchronizing multiple moving parts, ensuring every tool, no matter where, is tracked, monitored, and optimized in real time.

The ingrained habits of the industry present another barrier. There’s a noticeable hesitancy with decades rooted in traditional tooling management methodologies. Some might question the necessity of such a platform: “Why fix something if it isn’t broken?”

Lastly, the surge in digital solutions brings the specter of cybersecurity threats. Ensuring this data’s sanctity becomes paramount for a platform that leverages IoT sensors to transmit critical tooling data in real time.

While a tooling digitalization platform promises transformative benefits, navigating the hurdles to its full-scale adoption is an intricate endeavor. However, with the right platform that addresses these challenges, like eMoldino’s there’s a clear path to unlocking unprecedented efficiencies and insights in the automotive sector.

Reserve your free seat for the upcoming automotive webinar exploring the efficacy of tooling digitalization in addressing these critical challenges.

Increasing Tooling Digitalization Adoption

In the face of challenges confronting the automotive industry’s digitalization efforts, a tooling digitalization platform emerges as a technology and a solution.

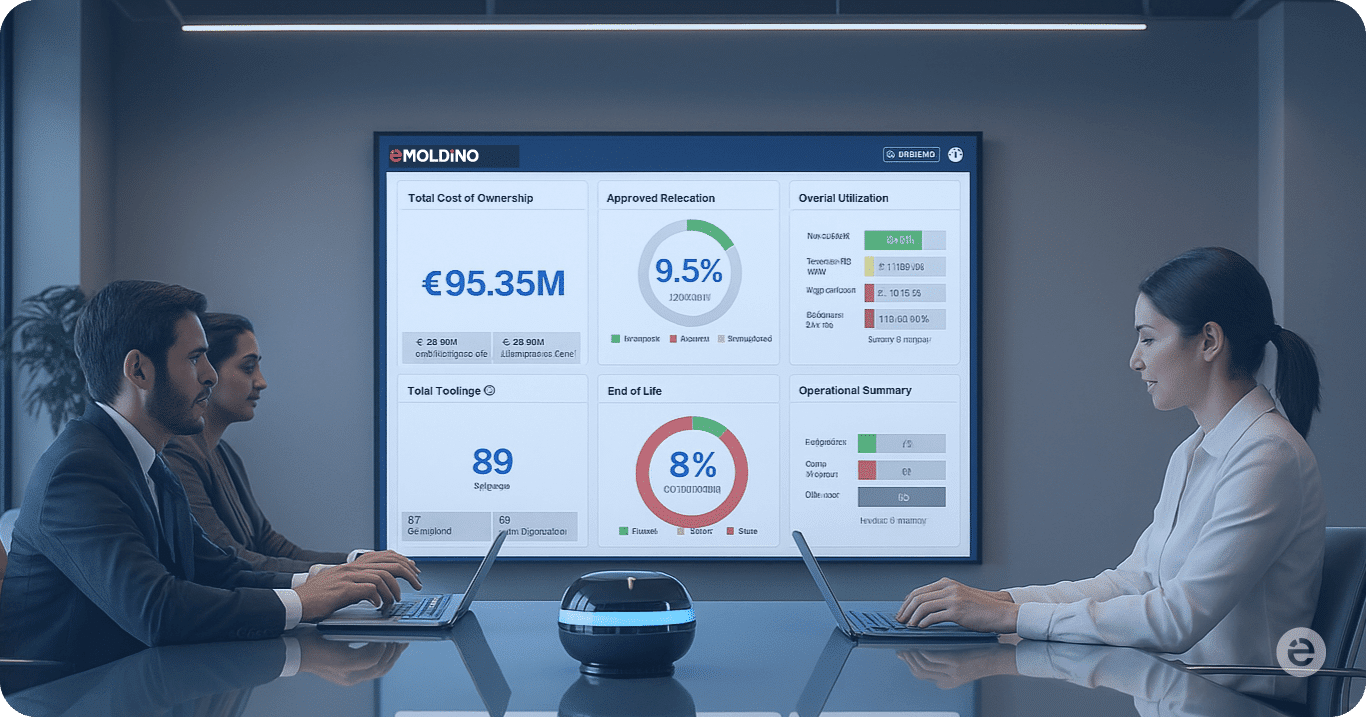

Addressing Financial Concerns: One of the critical apprehensions is the perceived high cost of transitioning to digital tooling. The platform’s design is a direct counter to this concern. By offering cost-effective integration, it ensures that large-scale investments yield tangible returns. Companies utilizing this platform have experienced a return on investments of $20 million from 2018 to 2023. Improving efficiency and minimizing waste is not just about spending money but making every dollar count, ultimately optimizing the total number of parts produced and the tooling costs.

Streamlining the Complex Supply Chain: With the intricacies of a global supply chain, synchronizing operations is paramount. The platform’s ingenious incorporation of IoT sensors provides a solution. It allows real-time monitoring of tooling fleets, irrespective of their global location. This gives executives visibility into their suppliers’ operations and offers granular insights into the number of parts produced, facilitating streamlined supply chain management. Identifying which suppliers provide the most reliable tooling prevents late parts delivery, ensuring an optimized and seamless supply chain.

Easing the Transition: Traditional methods, deeply ingrained within the industry, create a knowledge gap and cultural resistance. The platform actively addresses this by ensuring that the transition isn’t jarring. Comprehensive training modules and unwavering customer support make the shift from conventional to digital smooth. With easy-to-use dashboards, users can derive custom tooling insights, demystifying digital tooling and minimizing resistance.

Prioritizing Cybersecurity: The platform steps up in a world where data breaches are a real threat. Top-tier cybersecurity protocols ensure that the critical performance data transmitted by the IoT sensors remains protected. Its encrypted servers maintain the sanctity of the data, offering peace of mind to global companies that their intellectual properties and operational data are shielded from cyber threats.

Empowering Through Insights: Data is the new oil, but raw data is merely potential. The platform employs AI and ML to convert this potential into power. By transforming tooling data into actionable insights, it bridges the gap between having information and using it effectively. This allows all stakeholders to make informed supply chain decisions, optimizing their operations and boosting their bottom line.

Final Thoughts

The journey to digitalization in the automotive industry is neither straightforward nor without its challenges. However, the benefits of this transition—increased control over operations, enhanced product quality, optimized workflows, and reduced costs—are undeniable.

While barriers exist, solutions like eMoldino’s tooling digitalization platform illuminate the path forward. By choosing the right use cases and ensuring these use cases complement each other, the automotive industry can usher in a new era of digital excellence. In the relentless march of progress, those who adapt will thrive, while those who resist may be left in the rearview mirror. The automotive industry stands at a crossroads and the path to digital supremacy beckons.

Join the upcoming exclusive automotive webinar to learn more about tooling digitalization from industry experts and peers.

Explore Our Related Posts