Many companies adopt cycle time as a critical indicator of their operational efficiency. For executive leadership, optimizing cycle time translates directly to increased operational efficiency. This efficiency drives cost reductions and facilitates new revenue opportunities, underpinning improved business profitability. Given this metric’s critical nature, do companies really monitor cycle time?

“Cycle time deviation happens frequently; we need a solution to capture the variance. Tracking real-time Cycle time data can help reduce the cost of molded parts by 5~10%”.

– A Global consumer electronics company

Value Proposition of Monitoring Cycle Time

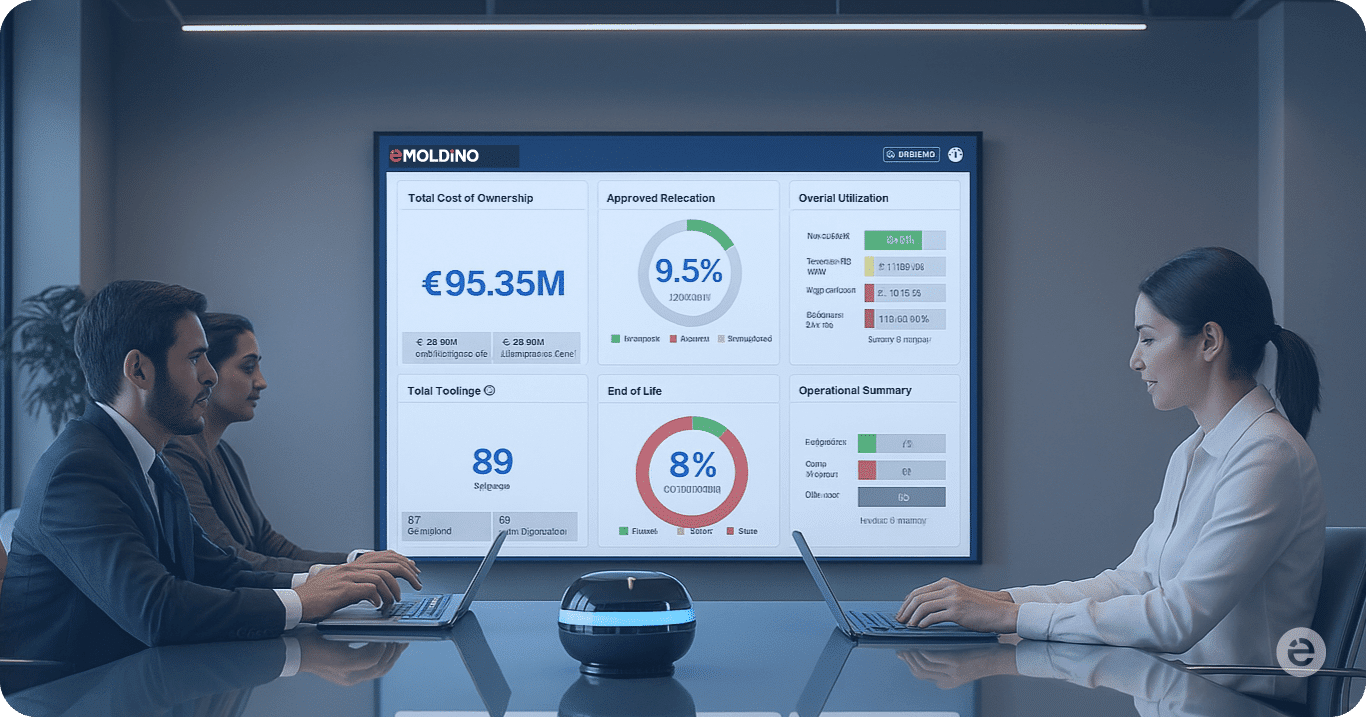

Real-time monitoring of cycle time, extending beyond the PPAP (Production Parts Approval Process) and RFQ (Request for Quotation) phases to include the entire ramp-up stage, provides crucial validation and compliance assurance, enabling ongoing operational adjustments and part cost negotiations. This enhanced visibility helps avoid unforeseen supplier-related cost which increases the need for additional tool purchases and provides critical data to C-level executives for strategic decision-making, directly impacting the bottom line directly impacting the bottom line and quality compliance issue caused by unapproved 4M change.

Proving the Value of Cycle Time Optimization

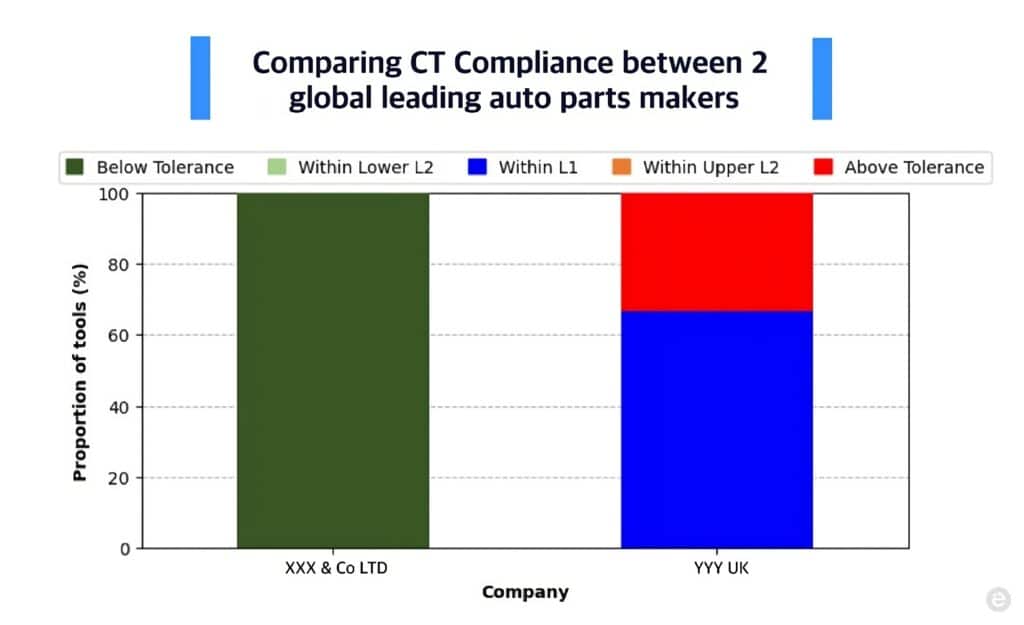

During a pilot program with a Global 500 automotive parts manufacturer, sensors on 5,000 molds revealed significant inefficiencies. Specifically, many tools operated at 50% slower than the optimal cycle time of 2 seconds per part.

This led to several financial risks :

- Potential price increases from suppliers due to higher per-part costs.

- The need to purchase new tools to maintain production levels.

- The possibility of sourcing new suppliers to meet demand.

- Recall claim due to unapproved 4M change

To address these challenges, a comprehensive analysis was conducted, uncovering the following key data points:

- Initially, 143 hours were required to meet production demands based on the approved cycle time.

- Observations indicated a requirement of 635 hours, revealing 492 additional hours.

- There was a 344% increase in required production hours, driven by an average cycle time deviation of 83% from the norm.

By implementing a tooling digitalization solution to optimize these deviations by 25% on 20% of their 5000 moulds, they effectively reduced excess hours. With a machine hour rate of $18,926.54 per tool, this optimization led to a risk mitigation saving of $9,463,518.02, demonstrating significant cost efficiency. This case study underscores the substantial financial benefits of precise cycle time management, including effective PPAP compliance, part cost negotiation, and machine hour validation, thus proving the undeniable value of investing in cycle time optimization technologies.

Final Thoughts

Effective cycle time management offers more than just operational efficiencies; it provides critical financial and strategic advantages. By prioritizing this metric, companies can ensure smoother operations, secure a more robust competitive stance in the market, and control sustainable product quality through compliance with approved PPAP processes.

How is your organization planning to integrate cycle time optimization to enhance its competitive edge?

About the author

eMoldino

eMoldino

eMoldino aims to digitalize, streamline, and transform your manufacturing and supply chain operations. We help global manufacturers who want to drive corporate innovation while maintaining the core values of collaboration and sustainability. Talk with us to learn more →

Did you enjoy reading this article?

2 / 5. Vote count: 1

Explore Our Latest Posts