背景介绍

在地缘政治和经济不稳定时期,汽车原始设备制造商及其供应商很容易受到影响。自 2020 年以来,危机和事件频发,导致供应链中断明显增加。例如,最近与关税相关的贸易紧张局势就对汽车制造商及其供应商构成了直接威胁。供应链中断如果处理不当,会对公司的产量、收入和盈利能力产生不利影响。因此,许多汽车原始设备制造商正在采取措施,通过数字化从内部和外部保护其全球供应链免受中断风险的影响。

问题

生产一辆汽车大约需要 30,000 个零部件。为了更高效地生产这些零部件,原始设备制造商将资源外包给整个汽车行业的 4000 多家供应商运营的 20 000 多个生产基地。在这个全球网络中,只要出现一个中断或瓶颈,就会破坏整个流程。由于缺乏对供应商的了解,原始设备制造商很容易受到影响,尤其是在发生 COVID-19 等突发事件时。事实上,美国汽车制造商在 2020 年的产量下降了 19%,原因是其全球供应商的大规模停产和复合延迟。在整个供应商网络中实施数字化解决方案,对于建立一个可承受并降低供应链风险的可持续、有弹性的网络至关重要。

解决方案

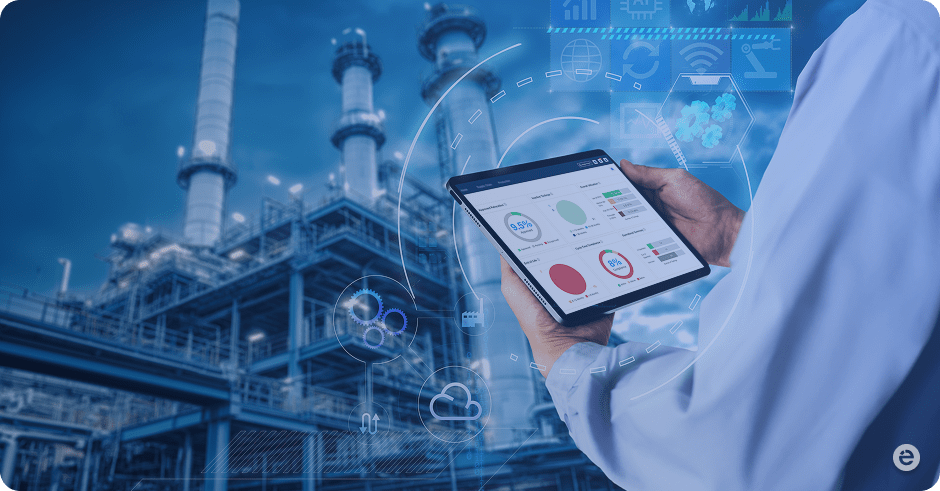

Catena-X 是一个解决方案的范例,主要的汽车原始设备制造商都采用了该解决方案,努力打造一个完全数字化的供应链。它是一个可互操作的开放式数据生态系统,支持原始设备制造商和供应商之间的安全数据交换。Catena-X 通过识别风险、中断或合规问题,实现供应链端到端的可视性。该公司成立于 2021 年,由宝马和大众等大型汽车原始设备制造商创立,旨在保护其供应链免受未来类似 COVID-19 的干扰。Catena-X 涵盖更广泛的整体供应链,但并不完全满足工厂车间对基本实时生产数据的需求。面对突发事件,仅有可视性是远远不够的。突发事件及其对供应链的影响瞬间发生。为了迅速果断地做出反应,原始设备制造商需要供应商一级的实时生产数据。

eMoldino 解决方案

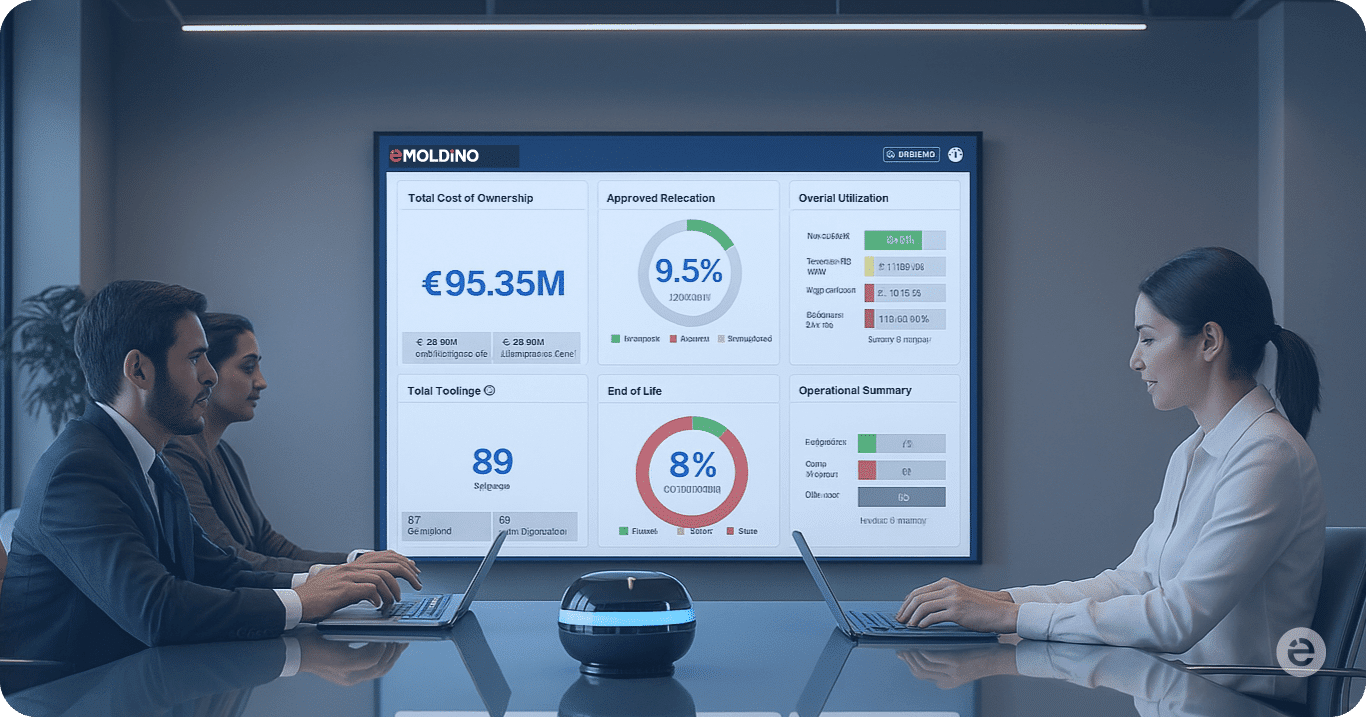

一个汽车原始设备制造商在所有供应商中拥有 $10B+ 的现有工具资产,而大多数原始设备制造商没有能力监控和跟踪这些昂贵资产的使用情况。事实上,据估计,原始设备制造商平均每年因资产管理不善而损失约 $5 亿美元。eMoldino 为汽车制造商和其他原始设备制造商提供其模具资产的实时生产数据。这些数据使原始设备制造商能够优化生产流程,更高效地生产零件,同时提高质量,即使在突发事件中也是如此。它还能为供应商提供与预防性维护相关的数据和警报,从而最大限度地延长这些昂贵资产的使用寿命。有了供应商网络的实时生产数据,原始设备制造商就能更好地为未来的中断做好准备。总之,通过 eMoldino 的解决方案,原始设备制造商及其供应商都能更好地应对供应链风险。

以下是 eMoldino 解决方案为客户带来的成果

JLR

在实施 eMoldino 解决方案的短短 10 个月内,产能提高了 20%,废品率降低了 38%。

PACCAR

实施 eMoldino 解决方案后,投资回报率达到 3.1 倍,节省成本 $700k。

摘要/结束语:

供应链中的中断风险不仅可能发生,而且不可避免。从自然灾害到地缘政治紧张局势和经济动荡,全球供应链始终很容易受到意想不到的冲击。当前主要经济体之间的贸易紧张局势就鲜明地提醒我们,贸易态势会迅速发生变化,并给供应商、定价和物流带来压力。eMoldino 的智能制造解决方案提供实时的模具生产数据,使供应商能够迅速应对中断,优化生产计划,并确保即使在意外发生时也能保持连续性。

关于作者

eMoldino

eMoldino

eMoldino 致力于数字化、简化和改造您的制造和供应链运营。我们帮助全球制造商推动企业创新,同时保持协作和可持续发展的核心价值。 请与我们联系,了解更多信息 →

您喜欢阅读这篇文章吗?

0 /5.计票: 0

浏览我们的最新文章