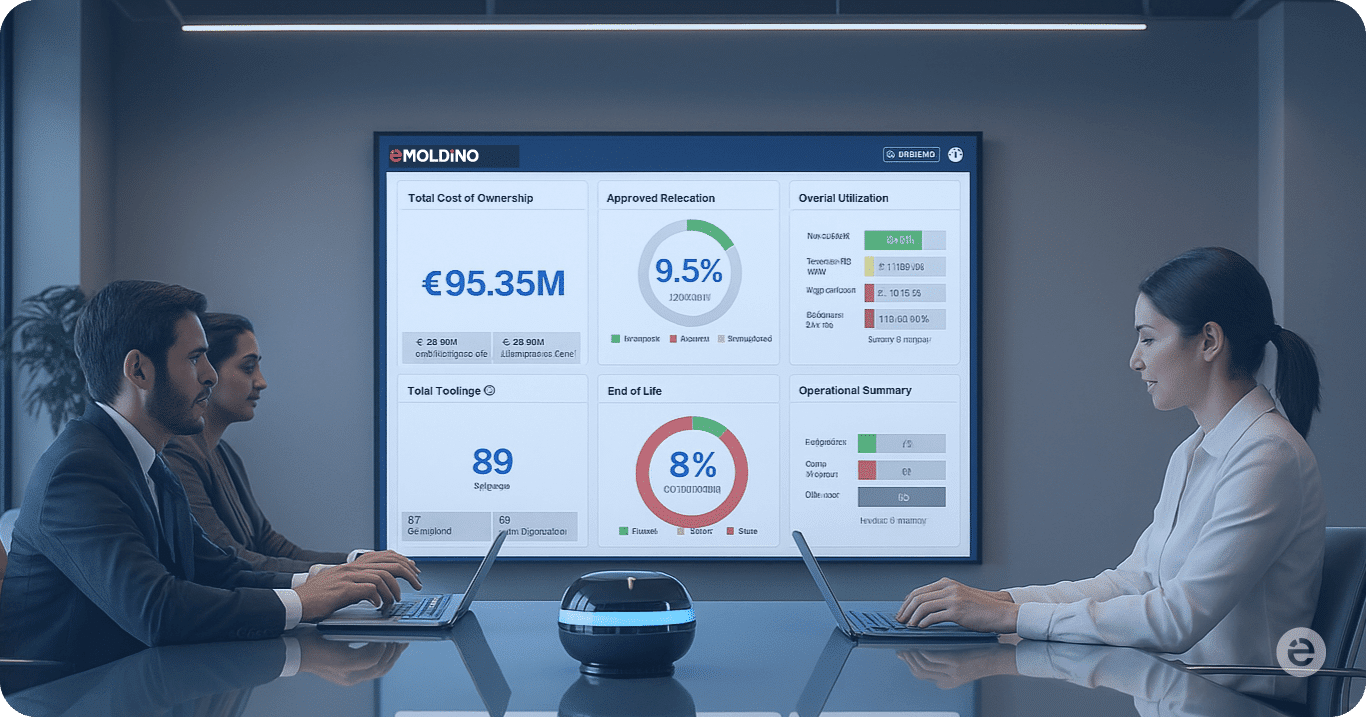

In today’s competitive manufacturing landscape, suppliers are under constant pressure by OEMs to deliver high-quality parts on time and to make sure tooling assets are properly maintained. Before eMoldino, efficient communication between OEMs and their suppliers was virtually impossible because neither side had access to data which could validate actual tooling and production conditions. eMoldino offers a supply chain intelligence solution which transforms traditional tooling management and parts-production processes through real-time data and AI-driven insights. Here’s how suppliers can benefit from adopting eMoldino’s solution:

1. Build Better Communication & Trust with OEMs

Transparency is key to strong supplier-OEM relationships. eMoldino provides real-time visibility to OEMs and suppliers into tooling performance, which facilitates transactions and discussions backed by actual data. The transparency provided by eMoldino’s solutions creates relationships which are built on trust. Automatic data logging of production cycles and tooling conditions eliminates guesswork and reduces disputes over delivery delays or mold-related issues. With both parties aligned on accurate data, communication improves and trust deepens.

2. Enhance Operational Efficiency and Achieve Cost Savings

Unplanned downtime can disrupt production schedules and damage supplier credibility. eMoldino’s predictive maintenance capabilities alerts suppliers before tooling failures occur. This proactive approach allows suppliers to plan maintenance in advance, align production schedules accordingly, and maintain steady output—significantly reducing costly interruptions. In addition, by identifying and addressing issues with tooling assets before they escalate, suppliers can reduce scrap rates. Real-time monitoring enables suppliers to detect issues early in the process and adjust conditions to prevent defects. The result is a more consistent output and fewer rejected parts, contributing to improved overall quality and OEM satisfaction.

3. Gain a Competitive Advantage

Many OEMs enforce strict compliance standards and impose penalties for late deliveries or tooling issues. With eMoldino’s real time production data, suppliers can easily prove adherence to quality and production standards. This not only minimizes audit risks but also helps avoid financial penalties and reputational damage. Suppliers who use eMoldino can showcase real-time tooling data and compliance metrics, demonstrating operational excellence and reliability. This positions them favorably in the eyes of OEMs and increases their chances of procuring new contracts.

Conclusión

eMoldino’s solution equips suppliers with the data needed to thrive in today’s high-pressure manufacturing environment. By leveraging real-time visibility and AI-powered insights, suppliers can streamline operations, reduce costs, and maintain superior quality standards. More importantly, they can build lasting trust with OEMs through transparency and data-backed performance. In an industry where reliability and speed matter most, eMoldino gives suppliers a clear competitive edge—enabling them not just to meet expectations, but to exceed them and secure long-term growth.

Sobre el autor

eMoldino

eMoldino

El objetivo de eMoldino es digitalizar, agilizar y transformar sus operaciones de fabricación y cadena de suministro. Ayudamos a los fabricantes globales que desean impulsar la innovación corporativa manteniendo los valores fundamentales de colaboración y sostenibilidad. Hable con nosotros para saber más →

¿Le ha gustado leer este artículo?

0 / 5. Recuento de votos: 0

Explore nuestras últimas publicaciones

Los OEM globales adoptan la tecnología de gestión de proveedores en tiempo real

Por qué los proveedores se benefician de la solución Smart Tooling de eMoldino

Protegido: Honeywell Boosts Tooling Efficiency with eMoldino’s IoT Innovations

Protegido: Eaton Saves Millions with eMoldino’s Tooling Digitalization Solution